|

Industrial Applications |

| » Metallurgical Industry |

|

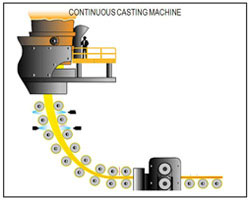

Continues Casting of steel

Secondary Cooling

For higher productivity secondary cooling plays critical part, the various rates of heat flux to be removed from hot slab at various stages of secondary cooling, spray nozzles are used for secondary cooling for this purpose single fluid, twin fluid spray nozzles are used. |

|

|

Descaling

During the process of cooling iron oxide scales are form on hot steel surface high pressure water jet are used to remove this scales from surface, for this purpose specially designed flat spray nozzle are use, operating pressure ranges from 80 to 450 bar. |

|

Roll Cooling

As the hot slab rolls through series of rolls the heat transfer happens because of mutual contact to recover this heat from rolls spray nozzles are used. This helps to improve shape control of rolls for optimum results on thickness of output product.

In steel industries spray nozzles are used for so many other applications elaborated as below : |

|

|

Coke quenching |

|

Gas cleaning and droplet separators |

|

Strip spray-off and blow-off |

|

|

Settlement of oxide dusts in the stand |

|

Intermediate stand cooling |

|

Strip surface quenching to protect the work rolls |

|

|

| » Chemical Industry |

|

Cleaning packing columns and Demister pads

Packing columns are used in chemical and petrochemical industries, for washing of packing materials / beds spray nozzles are used. Specially non-cloging spray nozzles are used for this purpose. |

|

|

Wet gas scrubber

To absorb chemical compounds from the gas some absorbents are spray into a gas scrubber, this for even distribution of absorbents spray nozzles are used. |

|

Cleaning of fermentation tanks and reactors

Specially designed self rotating and stationery spray nozzle are used to clean fermentation tanks and reactors. several types of cleaning agents and solvents can be used. |

|

| » Food and Beverages Industries |

|

Cooling and Heating (Pasteurization)

During the packaging of hot or cold foods full cone spray nozzles are used for thermal transfer, the uniform circular spray pattern helps to maintain uniform and steady heat transfer. In pasteurizing tunnels tangential entry hollow cone spray nozzles are used for both cooling or heating of packed cans, bottles, pouches of food or beverages. |

|

|

Sanitizing, Washing Bottles and canes

Spray nozzles and spray balls are used for sanitizing, washing and drying packaged or empty bottles / barrels. This is being used in automated packages and material handling equipments |

|

| » Pharmaceutical Industry |

|

Tablet coating

After making a good tablet, you must often coat it. The coating can have several functions. It can strengthen the tablet, control its release, improve its taste, colour, it makes it easier to handle and package, and protect it from moisture. |

|

|

Clean In Place (CIP)

For efficient cleaning of mixing tanks, containers, equipment, coating pans spray balls / turbo disc spray nozzles are installed inside the equipments made of pharma grade stainless steel which cleans the equipments in place. |

|

| » Automotive / Sheet Metal Industry |

|

Surface treatment

Surface treatment consist of several process stations like cold / hot water rising, degreasing, phosphatising, coating, galavnizing, and cleaning.

Full cone, Flat spray nozzles with quick release type assembly and clip on mountings are used to set in several spray angels, assemble and dismantle easily.

Surface treatment plays critical role in automotive and sheet metal industries as it is giving base for painting operations. |

|

|

Assembly and Quality Assurance

In the final stages of automotive production, many applications require the use of nozzles. These include sealing, dewaxing car bodies, vehicle washing, high-pressure cleaning and various simulation tests (e.g. corrosion tests, leak tests, aquaplaning tests). |

|

| » Paper Industry |

|

Coating

Surface sizing operations are performed to provide increased surface strength, as well as to produce paper with an increased resistance to penetration by liquid solutions. Treatment can also provide better surface characteristics and improve certain physical properties of the paper sheet. |

|

|

Showers and Oscillators

spray showers with the built-in cleaning device have been successfully used in paper mills around the world for years. A simple turn of the handwheel sweeps contaminants away from the nozzle orifices and directs all debris down the flush-out valve. |

|

Trimming

Paper trim and edge sprays are used in various sections of paper machines. Generally, they improve the mill speed and reduce risk of web breaks. Some machines use trim nozzles after the last drying roll as well. |

|

| » Fire Suppression for Tanks |

|

Spray irrigation of tanks aims to protect tanks and other vessels against unacceptable heating during burning. Here, heating must be understood as a condition where an increase of a tank’s inner pressure and a decrease of the tank walls’ resistance will lead to bursting of the tank. Also important is the heat-influenced breakdown of the sealing elements in detachable connections. Water spray simultaneously extinguishes and cools the complete surface of the incendiary matter. |

|

|

|

|